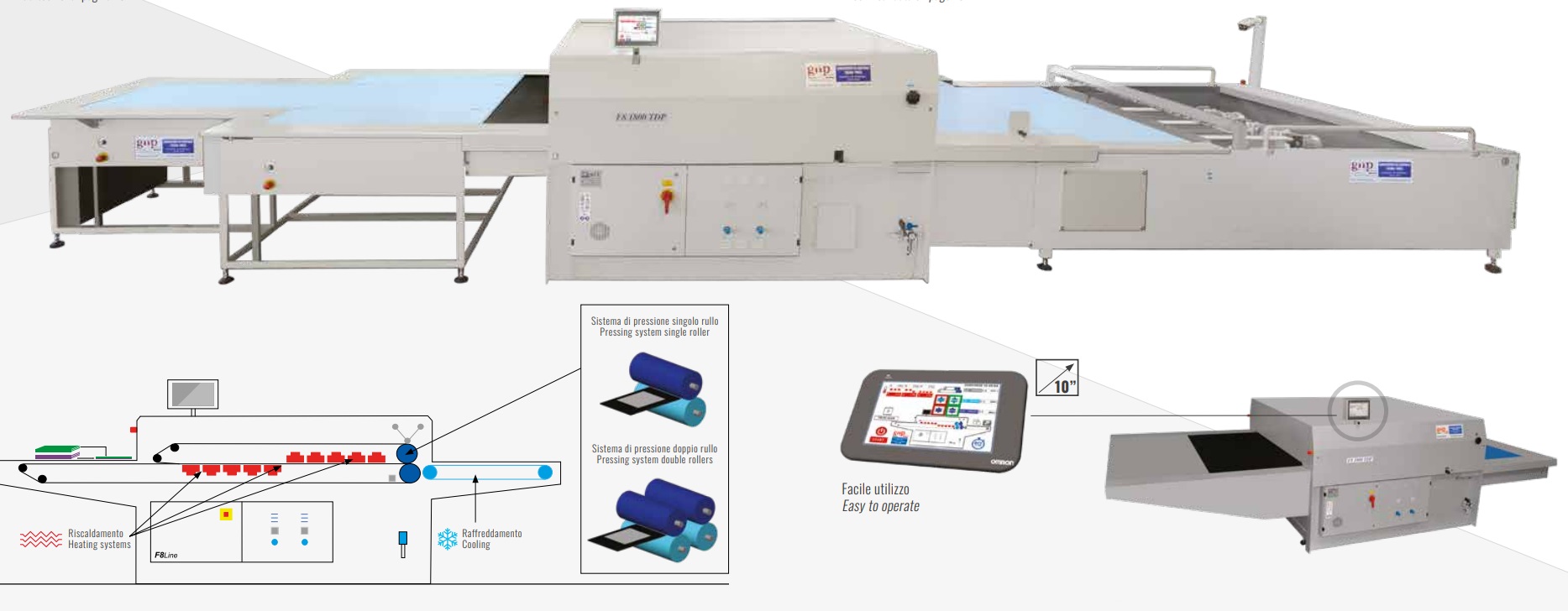

High quality fusing machine for clothing, outerwear, shirts and the leather. The machine is available with belt width 1100-1220-1400-1600-1830 mm (2000-2200-2500 mm on request).

It has a working area of 1100 mm long, which allows several operators to load the pieces to be bonded. Such area consists of a work surface and a belt section that easily receives the pieces to be loaded into the machine. The transport system consists of a lower belt and an upper belt, made of fiberglass with antistatic treatment, Teflon coated. Compensating rollers guide the belt, excluding the formation of folds and corrugations.

The 1400 mm long heating surface is composed of a series of 10 laminated profiles that form curved panels.

Each profile has an individual connection. The modularity of the construction ensures an extremely sensitive temperature control. The three heating zones are equipped with separate control circuits regulated by electronic thermostats, which simplifies determining the correct working settings for each single type of fabric and thermo-adhesive. The precision of this system allows to have tolerances that guarantee the best yield as well as ensuring the best adhesion with all materials. The support of the resistances guarantees the best contact of the fabric/material to the resistance. The pressing system can be single or double. The scraper bars in teflon graphite facilitate the total detachment of the processed pieces, finally the cooling station ensures that all pieces, whether unloaded by hand or automatically, cool down in such a way as not to leave marks. The machine is equipped with continuous manual upper and lower cleaning, by means of a flannel and a removable sock